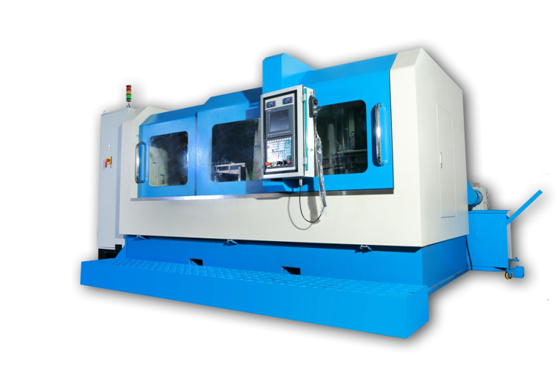

New Type: 2KB4-1-100 for Honeycomb Ceramic Mold Die

Honeycomb ceramics is a new ceramic products like a honeycomb structure in modern industrial development. The shape of the earliest is used as a catalyst carrier, used in automobile exhaust purification. Now the honeycomb ceramics has been widely used in chemical, petroleum, metallurgy, electrical, electronic and electrical appliances, machinery and other industries, the development prospect is considerable in this industry.

2KB4-1-100 is special designed for honeycomb ceramic mold die by HTT. Die holes in different positions can be programmed to automatically complete the whole drilling process. hole diameter range: : Φ1.1-4mm, maximum drilling depth: 100mm, X1 /X2/Y1/Y2 travel: 500mm, Max.spindle speed 15000r/min. The new generation of Synetc 200MA CNC system.

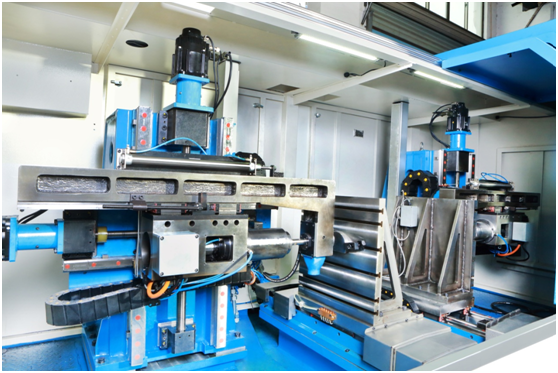

Drilling machine is structured with X1&X, Y1&Y2, Z1&Z2; Z1 axis and Z2 axis CNC CNC sliding are respectively arranged a drilling spindle.

When processing, workpieces will be fixtured on the X1&X2 axis, set the starting position of machining die hole starting position and gun drill according to the location and depth of processing die hole, input processing parameters, the machine starts, Z1 and Z2 CNC feeding and moving at the same time, after feed processing complete. Z1 and Z2 CNC slide back, X1&X2, Y1&Y2 displacement to the position of another die hole, then repeat the process on the feed, to complete the processing. The machine can also be processed simultaneously in two different specifications of the mould.

Only manual clamping workpiece in the whole process .input processing parameters, the hole pitch and spacing can be programmed by control system to calculate.