What is deep hole drilling?

What is deep hole drilling?

Deep hole drilling is where the hole depth to diameter can be upto 400:1 ratio. Deep hole drilling consists of two techniques: Gun Drilling & BTA Drilling.

GUN DRILLING

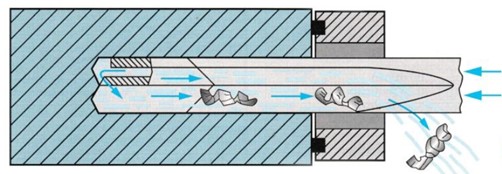

Gundrilling is a deep hole drilling process that uses a long cutting tool to produce holes in metal at large depth-to-diameter ratios. Gun drilling is effective in diameters from 1 – 50 mm [0.04 – 2.00 in]. A gundrill tool differs from a conventional twist drill by its unique shank and head geometry; a standard gundrill has a V shape groove to flash our chips and oil with built in coolant hole in the tool.

The gundrilling process is able to drill deep holes beyond what is possible with conventional machinery and tooling such as twist drills, by using high pressure coolant for clean chip exhaust, even at extreme depths.

Gun drilling was initially developed for the manufacture of gun barrels, where both straightness and barrel durability were essential to properly functioning barrels.

Gradually the gun drilling technology is adopted by any industry which require long straight holes and difficult to achieve with twist drill. The industries include mold and die making, auto parts, fuel common rail, engine valve, pellet die, cannulated medical drill, cam shaft, crank shaft, ….. for any industry as applications need a long straight hole.